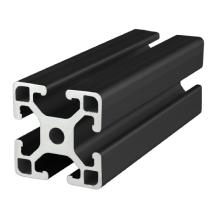

Where T-Nuts Fit Into the Picture

If fasteners are the backbone of your build, T-nuts are the lifeblood.

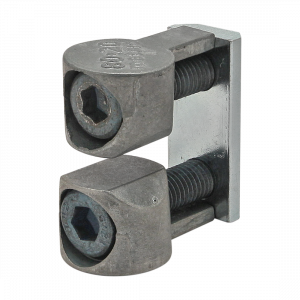

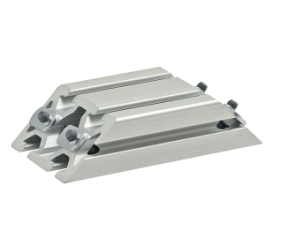

T-nuts slide into the T-slot of your extrusion and provide threaded anchor points for bolts and fasteners. When used in tandem with inside fasteners, they allow for rock-solid, hidden connections that keep your frame clean and strong.

Different T-nut types (drop-in, roll-in, spring-loaded) offer various advantages depending on your application. And yes, we stock them all—because every great build starts with a solid foundation.

Choosing the Right Combo: Building Smarter with Modular1

Here’s the thing: hardware shouldn’t hold you back. It should open up possibilities.

At Modular1, we’re not just selling fasteners—we’re building better ways to build.

So when you’re choosing between inside fasteners, end fasteners, T-nuts, or corner connectors, think about the bigger picture:

Is this a permanent structure or will it need frequent changes?

Do you care more about aesthetics or speed of assembly?

Will your build be exposed to vibration, heavy loads, or environmental factors?

We’ve designed our product range to work together like a well-oiled machine—giving you ultimate flexibility, security, and peace of mind.

Need Help? We’ve Got You.

Not sure which inside fastener size is right? Confused between a corner connector and a double connector?

We’ve been in this game for a while—and we’ve seen it all. Our support team is made up of real people who know their way around a T-slot. Drop us a line and we’ll help you pick the perfect parts for your next build.

Accessories

Accessories Liner Motion

Liner Motion Panels

Panels Tools

Tools Fastners

Fastners Framing Solution

Framing Solution