Must-Know Types of Screws (With Examples & Best Uses)

Choosing the right screw might seem simple, but with so many variations, it’s easy to get confused. Screws come in a wide range of shapes, sizes, and thread types, each suited to specific tasks. Whether you’re building furniture or tackling industrial jobs, understanding the types of screws ensures strength, safety, and style.

What Are Screws?

Screws are threaded fasteners designed to hold objects together or position them precisely. Used in woodworking, metal fabrication, construction, and even electronics, screws provide torque-driven grip that resists vibration, loosening, and wear over time. They usually work in combination with a matching nut or by threading directly into a material.

Anatomy of a Screw

Before diving into types, let’s decode the basic parts of a screw:

- Head – The top part you drive in.

- Thread – The helical ridge that grips the material.

- Drive – The slot or shape that fits the tool.

- Point – The tip that initiates the cut or bite.

Why Screw Selection Matters

Common T Slot Profiles and Standards

Using the wrong type of screw can lead to material damage, structural failure, or rusting. The correct screw boosts efficiency, ensures longevity, and supports aesthetic goals. So, choosing based on head shape, threading, and material compatibility is crucial.

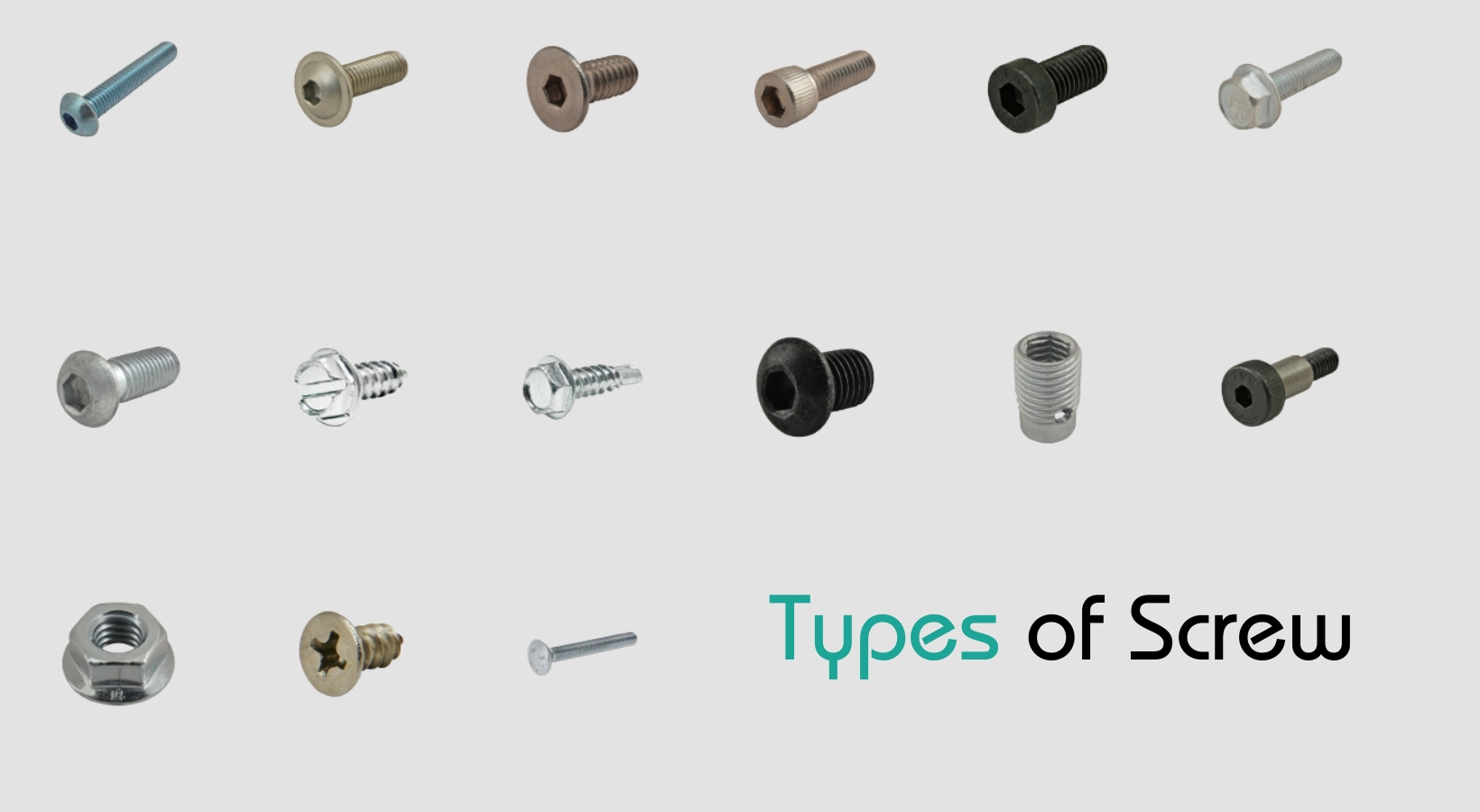

Types of Screws Based on Head Type

1. Flat Head Screws

These sit flush with the material surface, ideal for countersinking in wood and drywall. They offer a clean, hidden finish.

2. Round Head Screws

Round heads stick out slightly and are perfect for attaching soft or thin materials like sheet metal without the risk of pull-through.

3. Button Head Screws

Best in Class: Modolur1 Button Head Screws

Button head screws are stylish, low-profile fasteners with a rounded top and larger diameter. They’re ideal for assemblies that require a neat appearance with broad surface support.

Modolur1’s Button Head Screws are trusted for:

- Aesthetic Designs – Sleek curves make them perfect for furniture and automotive interiors.

- Superior Strength – Made from high-grade alloy steel or stainless steel.

- Rust Resistance – Ideal for indoor and outdoor use.

- Precision Manufacturing – Ensures consistent threading and fit.

Shop Modolur1 Button Head Screws now for quality and class that lasts.

4. Pan Head Screws

Similar to button heads but with a flatter top, they offer excellent torque and are often used in electronics.

5. Truss Head Screws

With a wide, rounded top, they’re great for holding thin materials without tearing through them.

Types of Screws Based on Drive Type

6. Slotted Drive Screws

The oldest type is just a straight line, but it can easily slip or come out during driving.

7. Phillips Drive Screws

Cross-shaped heads offer more stability and are ideal for hand or power tools.

8. Hex Drive Screws

Perfect for heavy-duty applications, using Allen keys or hex drivers to tighten.

9. Torx Drive Screws

Star-shaped designs provide great grip and are increasingly used in electronics and auto manufacturing.

Types of Screws by Thread Type

10. Machine Screws

Uniform, fine threads are used in pre-threaded holes or nuts, especially in machinery and devices.

11. Wood Screws

Coarse threads tapering to a sharp point, ideal for biting into softwood and hardwood.

12. Sheet Metal Screws

Designed to cut into thin metals with high torque and coarse threading.

13. Self-Tapping Screws

No pilot hole needed, these screws tap their own threads into soft metals or plastics.

14. Drywall Screws

Specifically engineered to secure drywall sheets to studs, with deeper threads for a firm grip.

Types of Screws by Application

15. Construction Screws

Typically heavy-duty with deep threads, great for framing, decking, or subfloor installations.

16. Electronics Screws

Miniature in size with precise threading, usually in Torx or Phillips drives.

17. Automotive Screws

Designed to handle heat, vibration, and corrosion; often come with built-in washers.

18. Furniture Screws

Often decorative or hidden, these offer easy assembly and good surface hold.

Specialty Screws and Security Screws

Need extra safety or custom functionality? Consider tamper-proof screws, one-way screws, and reusable socket head screws used in commercial setups or restricted-access areas.

Tips for Choosing the Right Screw

When in doubt, consider:

- Material Compatibility – Use stainless steel for moisture-heavy areas.

- Thread Type – Coarse for wood, fine for metal.

- Length and Diameter – Depends on load and penetration depth.

- Head Type – Choose button, pan, or flat for specific finishes.

Tools You’ll Need for Screw Installation

| Tool | Use |

|---|---|

| Screwdrivers | Manual driving |

| Drill/Driver | Quick, powered driving |

| Allen Wrench | For hex drive screws |

| Torque Wrench | Controlled pressure for machine work |

Why Choose Modolur1 Button Head Screws?

Modolur1 is a trusted name in the fastener world, offering precision-engineered screws that blend form and function.

Key Features:

- High corrosion resistance

- Consistent drive engagement

- Elegant, rounded head for modern designs

- Available in various sizes and finishes

Perfect for industrial, commercial, and DIY use.

Conclusion

Choosing the right screw saves you time, money, and frustration. From button heads to drywall screws, understanding the types of screws makes any project easier and more durable. And when quality matters, you can count on Modolur1 Button Head Screws for precision, durability, and style.

Frequently Asked Questions

1. What is the strongest type of screw?

2. Which screw is best for wood?

3. Are button head screws better than flat head?

4. Can you use metal screws on wood?

5. What does “self-tapping” mean?