T vs V-Slot Aluminium: Which One is Right for Your Project

When it comes to modular framing systems, aluminium extrusion profiles are a go-to material for DIYers, engineers, and manufacturers alike. Two of the most commonly used types are T and V-Slotted aluminium profiles, but how do they differ? Which one is right for your specific application? And most importantly, how does Modular1 T Slot Aluminum rise above the competition?

Let’s dive into a full comparison to help you make an informed decision.

Understanding Aluminium Profiles in Industrial Design

Aluminium extrusion profiles have revolutionized project design in everything from workstations and machine guards to 3D printers and robotics.

They offer:

- Flexibility: Easily customizable structures.

- Strength: Robust yet lightweight.

- Corrosion Resistance: Perfect for industrial settings.

Role of Slotting in Modular Design Systems

Slotting, either T or V, adds a standardized connection path along the length of an aluminium extrusion. This allows the attachment of brackets, fasteners, panels, or even linear motion components without complex machining.

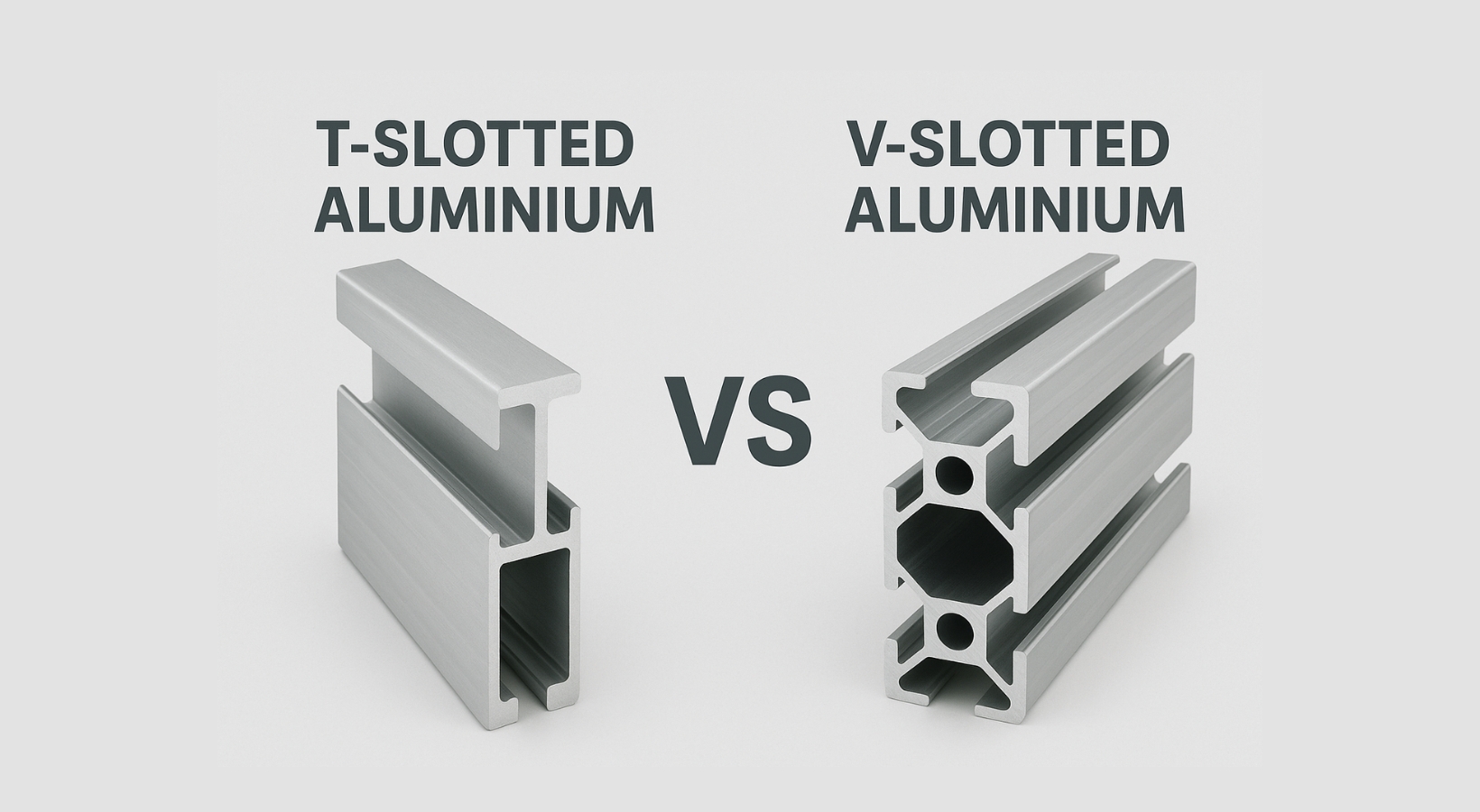

What is T-Slotted Aluminium?

T-Slotted aluminium features a “T”-shaped channel that accepts standard connectors and fasteners. The T-slot design is perfect for building frames, enclosures, and heavy-duty supports.

Key Features of T-Slot Aluminium Extrusions

- Easy to cut, assemble, and reconfigure.

- Highly modular and compatible with a range of accessories.

- Stronger joints for heavy-load applications.

Industries Where T-Slots Excel

- Industrial automation

- Machine framing

- Custom workbenches

- CNC machine bases

Modular1 T Slot Aluminum

Modular1 T Slot Aluminum stands out due to its precision machining, wide compatibility, and excellent durability. Profiles support a variety of slot sizes and are tested to perform in high-stress industrial environments.

Why Modular1?

- High-grade aluminium for enhanced strength.

- Compatibility with international T-slot standards.

- Exceptional customer support and rapid delivery.

- Trusted by engineers and makers across industries.

What is V-Slotted Aluminium?

V-Slotted aluminium features a “V” groove designed for integrated linear motion. This profile doubles as a guide rail for wheels and rollers, making it ideal for dynamic assemblies.

Advantages of V-Slot Aluminium Profiles

- Built-in linear track system

- Clean, sleek appearance

- Ideal for precise movement

Common Projects Using V-Slot Profiles

- 3D printers

- DIY laser cutters

- Camera sliders

- Lightweight motion frames

Side-by-Side Comparison: T vs V-Slot

| Feature | T-Slot Aluminium | V-Slot Aluminium |

|---|---|---|

| Connection Strength | Stronger joints | Moderate strength |

| Linear Motion | Requires add-ons | Built-in track |

| Applications | Heavy-duty frames | Motion-based devices |

| Ease of Assembly | High | Moderate |

| Cost | Mid-range | Often higher |

Modular1 T Slot Aluminum stands out due to its precision machining, wide compatibility, and excellent durability. Profiles support a variety of slot sizes and are tested to perform in high-stress industrial environments.

Which One is Easier to Work With?

T-Slots are easier for heavy and static structures, while V-Slots are better when integrated motion is essential.

Cost and Availability Comparison

T-slot profiles, like those from Modular1, are more widely available and cost-effective in larger projects. V-slot is popular in niche markets like desktop fabrication tools.

Choosing the Right Aluminium Profile for Your Project

Structural Needs and Load Bearing

If your project demands strong load-bearing capacity, like a machine base, T-slot is the winner.

Motion and Aesthetic Design

If motion is central, such as in sliders or robotics, V-slot provides an elegant and functional option.

Why Modular1 is the Ideal Choice for T-Slot Projects

Modular1 doesn’t just sell aluminium profiles, supports engineers in building scalable, future-proof systems. Whether you’re setting up a new lab or automating a production line, our T-slot extrusions deliver performance and reliability.

Installation and Maintenance Tips

- Use high-torque fasteners for stronger joints.

- Clean the slots before mounting components.

- Use corner brackets for improved stability.

Tools and Accessories Needed

- Allen keys

- T-nuts and brackets

- Rubber hammer for tapping joints

Sustainability and Recycling of Aluminium Profiles

Both T and V-slotted profiles are 100% recyclable. Aluminium is one of the most sustainable construction materials, with a low environmental footprint.

Conclusion

So, which T vs V-Slotted Aluminium should you pick?

- Choose T-Slotted aluminium, especially from Modular1, if your project requires modularity, strength, and long-term scalability.

- Choose V-Slotted aluminium if your build demands integrated motion with a lighter touch.

Frequently Asked Questions

1. Can you use V-slot components on T-slot extrusions?

2. Is T-slot aluminium reusable?

3. Which is more beginner-friendly?

4. Can T-slot aluminium be used outdoors?

5. Is Modular1 only for industrial clients?

6. Where can you buy Modular1 T Slot Aluminum?