How to Cut T Slot Aluminum Like a Pro: Expert Tips to Maximize Performance

Cutting T Slot aluminum may seem like a job best left to machinists, but with the right tools and techniques, it’s a task anyone can master. Whether you’re assembling a CNC machine, a 3D printer frame, or a modular workstation, precise cuts are key to a successful build. And when you’re using Modular1’s T Slot Profile, you’re already halfway there, thanks to its high-grade finish, superior straightness, and easy-to-machine design.

In this post, you’ll learn how to cut T Slot aluminum safely and accurately while getting the most out of Modular1’s exceptional profiles.

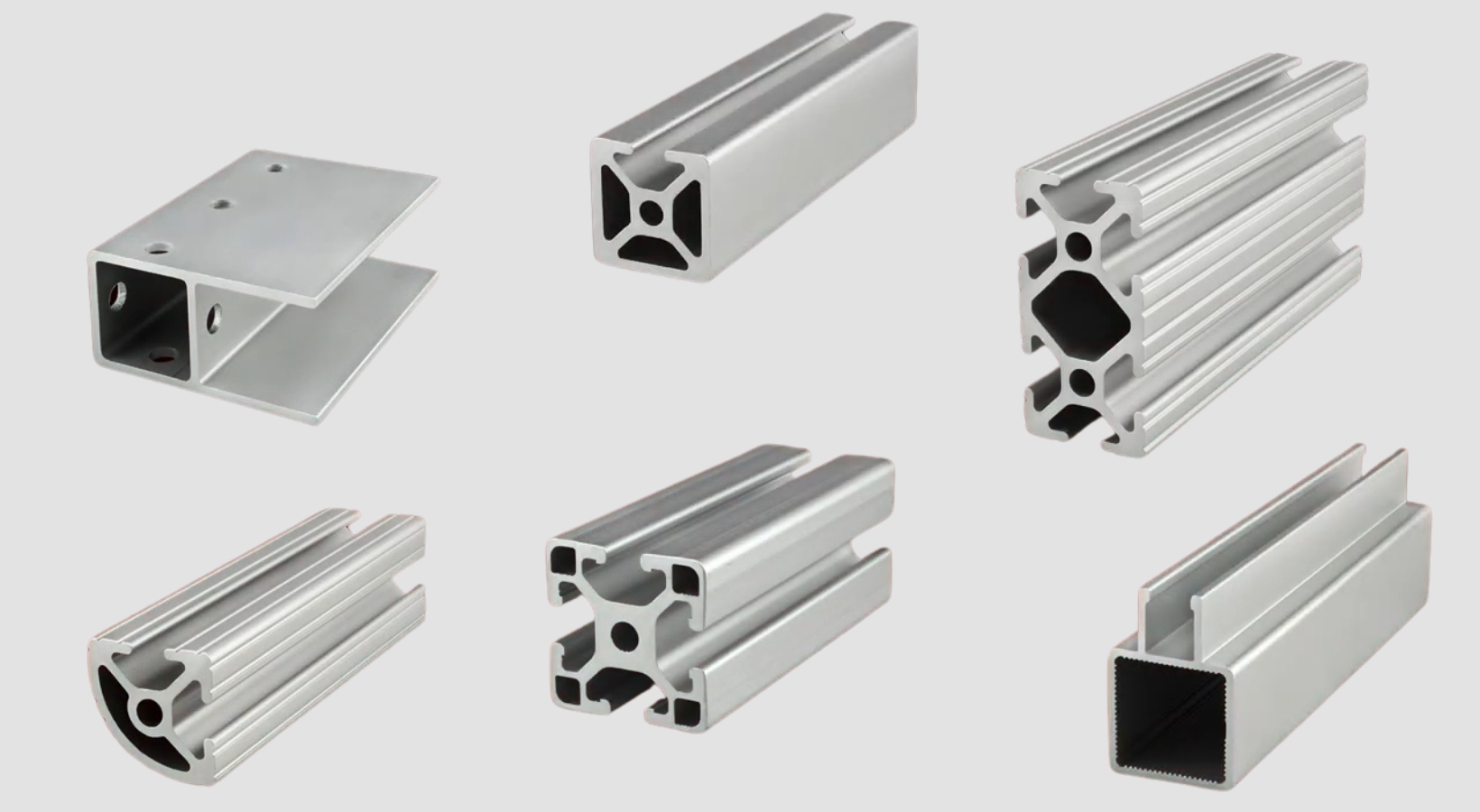

T Slot Aluminum

T Slot aluminum is an extruded profile designed with a “T” shaped groove running along its length. This groove allows for versatile assembly by enabling bolts, fasteners, and brackets to slide and lock into place.

Common Applications in DIY and Industry

- CNC machine frames

- 3D printers

- Workstations and shelving

- Automation systems

- Furniture and custom enclosures

Tools Required for Cutting T Slot Aluminum

Manual Tools

- Hacksaw: Ideal for simple shortcuts.

- Miter Box: Ensures straight angles when using hand tools.

Power Tools

- Miter Saw with Carbide Blade: Most efficient for clean cuts.

- Chop Saw: Fast and effective with the right blade.

- Bandsaw: Smooth, continuous cuts for long lengths.

Safety Equipment

- Eye protection

- Hearing protection

- Clamps or vices to stabilize the profile

- Gloves (optional, but useful during deburring)

Preparing the Workspace

Securing the Aluminum

Before making any cuts, secure the T Slot profile using a vice or clamps. Stability is key to preventing blade drift or injury.

Marking Your Cuts Accurately

Use a square, measuring tape, and a fine-point marker or scribe. Double-check measurements, especially for builds requiring high precision.

Step-by-Step Guide to Cut T Slot Aluminum

Step 1: Measuring and Marking

Measure twice, cut once. Always account for blade kerf (thickness of the blade) to avoid shortening your piece.

Step 2: Choosing the Right Blade

Use a carbide-tipped blade with 80+ teeth per inch (TPI). These are designed for non-ferrous metals like aluminum.

Step 3: Cutting Technique

- Let the blade do the work; don’t force the aluminum.

- Maintain a steady feed rate.

- Cut slowly to minimize chatter or vibration.

Step 4: Post-Cut Finishing

After the cut, deburr the edges with a file or sanding block. A smooth edge improves fitting and prevents injury during assembly.

Best Blades for Aluminum Profiles

| Blade Type | Ideal Use | Notes |

|---|---|---|

| Carbide-Tipped | Miter or Chop Saws | Long-lasting and precise |

| Abrasive Disc | Chop Saw | Wears faster, more debris |

| Fine TPI Blade | Bandsaw | Smooth, clean cuts |

Use lubricant sprays like WD-40 to reduce heat and friction during cutting, especially for long sessions.

Common Mistakes to Avoid

- Using Wood Blades: These dull quickly and can damage the profile.

- Skipping Blade Alignment: Leads to angled cuts and unusable pieces.

- Not Wearing Safety Gear: Metal shavings can cause serious injury.

Modular1’s T Slot Profile: An Overview

Modular1 offers a premium line of T Slot aluminum profiles that are perfectly suited for cutting and modular construction.

What Makes Modular1 Unique?

- Aircraft-grade aluminum

- Anodized finish for corrosion resistance

- Straightness tolerance that minimizes the need for rework

- Wide range of profile sizes and accessories

Why Choose Modular1 for T Slot Projects

Compatibility with Multiple Builds

Whether it’s automation, prototyping, or heavy-duty setups, Modular1’s profiles adapt easily. Our standardized slot sizing ensures cross-compatibility with fasteners and joints from other systems.

Compatibility with Multiple Builds

The profiles are designed with machinability in mind. Minimal burrs, no internal voids, and accurate extrusion mean fewer errors in your build.

Pro Tips for Clean and Accurate Cuts

- Use a Jig or Guide Rail: Helps maintain cut angles.

- Feed Slowly: Rushing leads to uneven cuts and blade damage.

- Deburr Every Cut: Especially important before assembly to ensure tight fits.

Assembly After Cutting

Fitting T Slot Connectors

Once cut, insert Modular1’s brackets, fasteners, or gussets to assemble the frame. Our system is modular, with no welding or heavy tools required.

Accessories That Simplify Assembly

- T-nuts

- Corner brackets

- End caps

- Leveling feet

Modular1 includes precise instructions and kits tailored to various applications.

Maintenance of Your T Slot Aluminum Tools

- Sharpen Your Blades: After 20–30 cuts, inspect for dullness.

- Clean Aluminum Dust: : Use a vacuum or brush to clear your workspace.

- Store Blades Safely: Protect against warping and rust.

Comparing Modular1 with Other T Slot Brands

| Feature | Modular1 | Generic Brands |

|---|---|---|

| Precision | High tolerance | Inconsistent |

| Finish | Anodized, smooth | Rough cut |

| Support | Technical support available | Minimal or none |

| Accessories | Full ecosystem | Limited compatibility |

Final Thoughts

Knowing how to cut T Slot aluminum opens doors to limitless DIY and industrial possibilities. With the right tools and techniques, clean and precise cuts become simple, even for beginners. When you choose Modular1’s T Slot Profile, you’re investing in ease of cutting, perfect alignment, and superior build quality.

Whether you’re building a custom machine or setting up a new workspace, trust Modular1 to deliver performance, flexibility, and style, all cut to perfection.

Frequently Asked Questions

1. Can you cut T Slot aluminum with a regular saw?

Yes, but only if you use a fine-tooth, carbide-tipped blade suitable for aluminum.

2. Is lubrication necessary when cutting?

It helps reduce heat and extend blade life, especially with repeated cuts.

3. What’s the best way to deburr the ends?

Use a file or rotary deburring tool, then smooth with sandpaper.

4. Do you need special clamps to hold T Slot profiles while cutting?

A standard vice or quick-release clamp works well; just avoid crushing the profile.

5. Are Modular1 profiles easier to cut than others?

Yes. They’re manufactured to strict tolerances and with a smoother finish, which aids clean cuts.

6. How do you ensure square cuts every time?

Use a miter saw with an adjustable fence or a jig. Mark carefully with a square before each cut.